Sheet Metal

Inflite Engineering has two facilities dedicated to the manufacture and fabrication of sheet metal components. Inflite produce simple detailed parts up to large multi-level assemblies across numerous platforms, covering both civil and military aircraft supporting key aerospace OEMs and Tier 1 suppliers.

Processes include profiling of aluminium, and hard metals by means of routing and water jet cutting, hot and cold forming of sheet and tube material including pressing, stretch forming and wheeling. These are supported by our onsite heat treatment department and our capability to carry out non-destructive testing, TIG, resistance and gas welding, all of which have held NadCap accreditation since 2007.

Processes include:

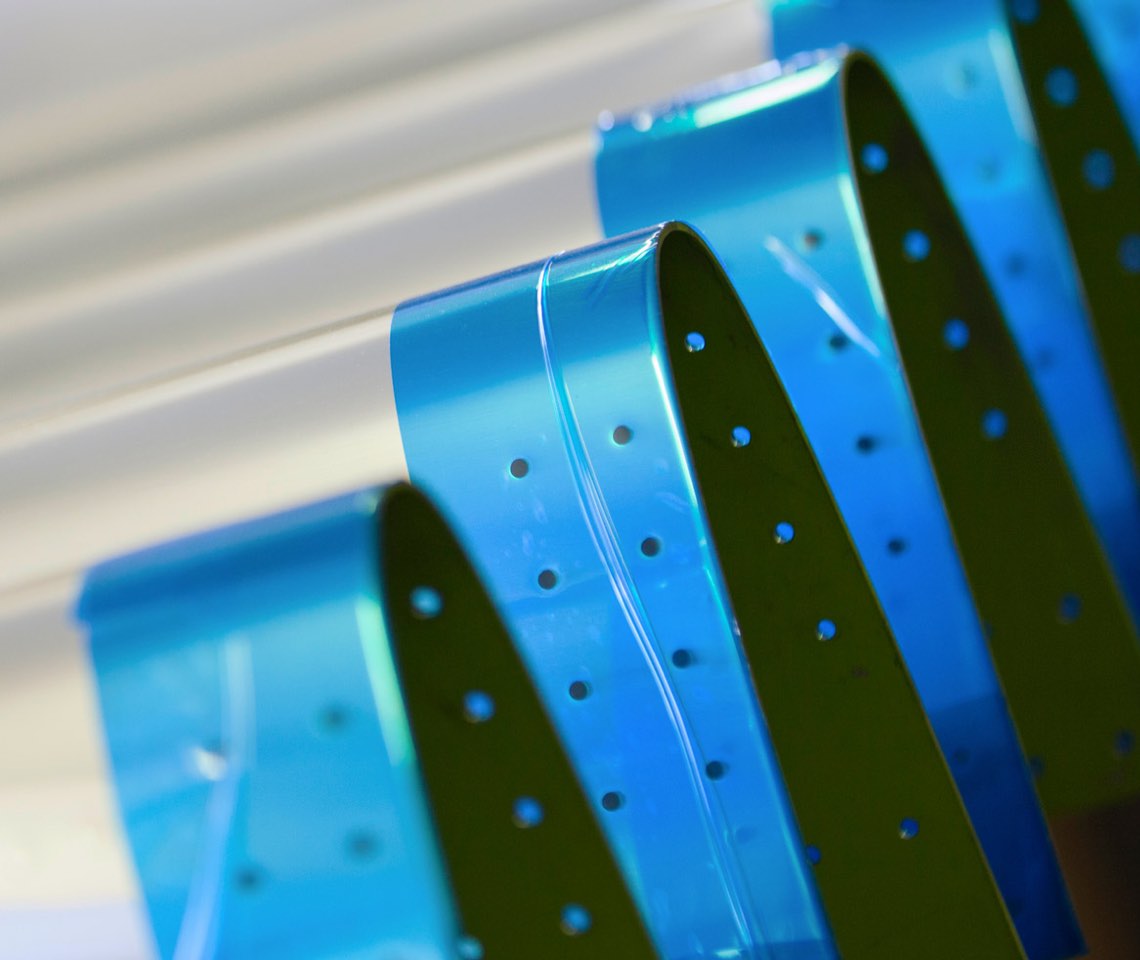

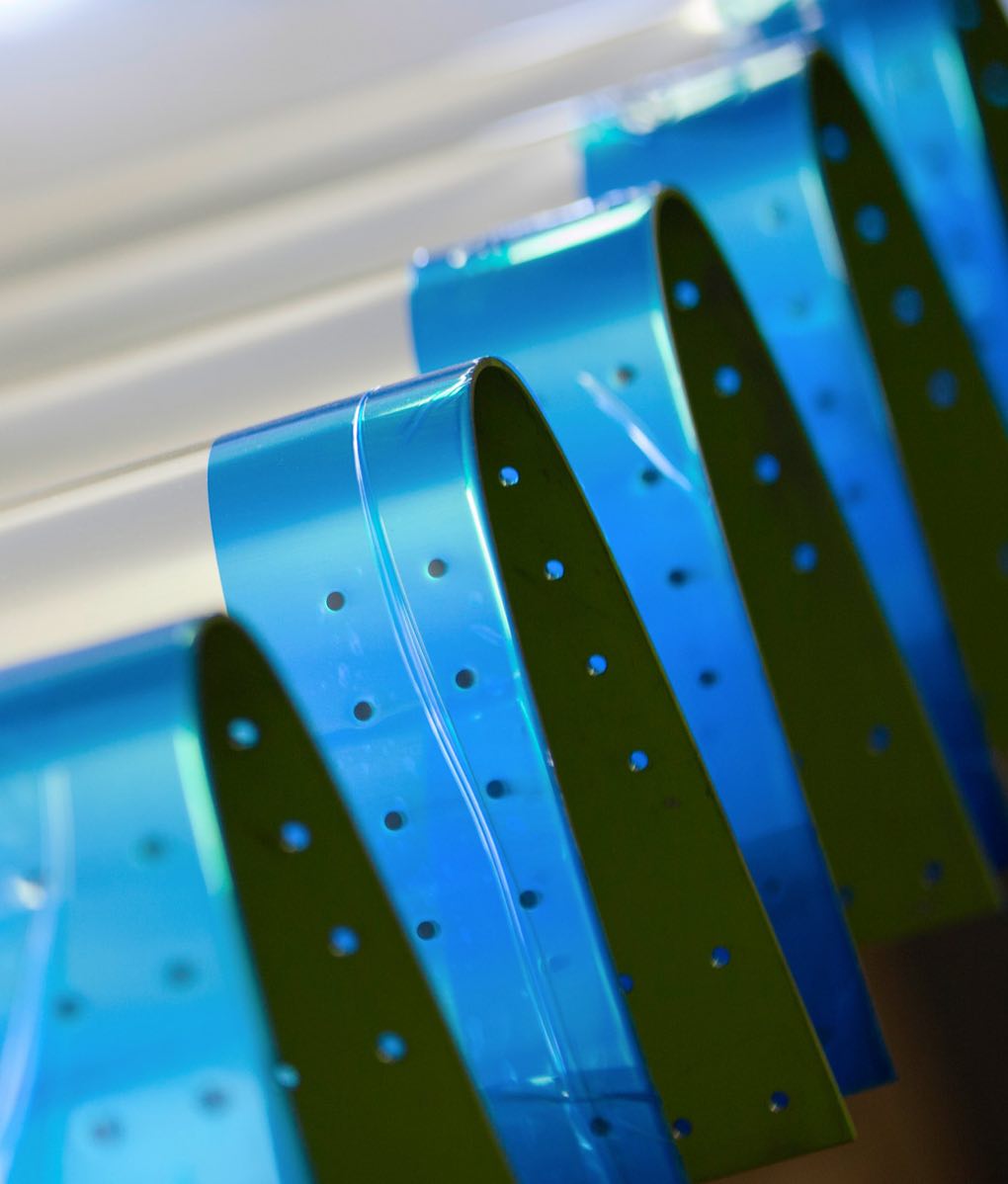

Sheet metal forming

- Triple Action Presses

- Rubber Presses

- Hold and Cold Draw Forming

- Brake Pressing

- Stretch Forming

- Pattern Development

- Hot Spin dimpling

Sheet metal profiling

- Waterjet profile/cutting, various metals

- CNC 2 and 5 axis metal routing

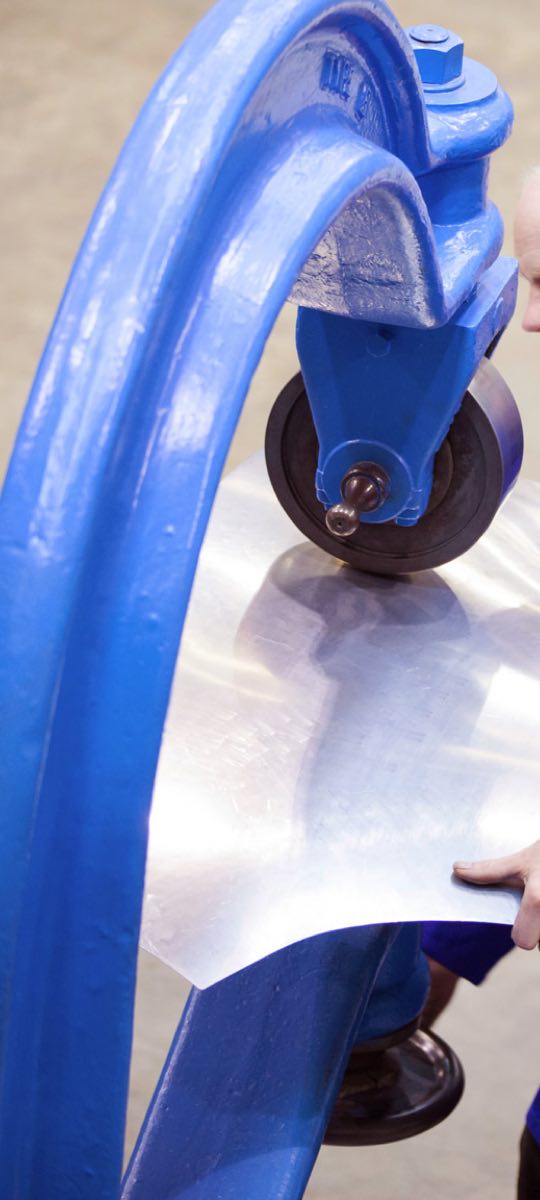

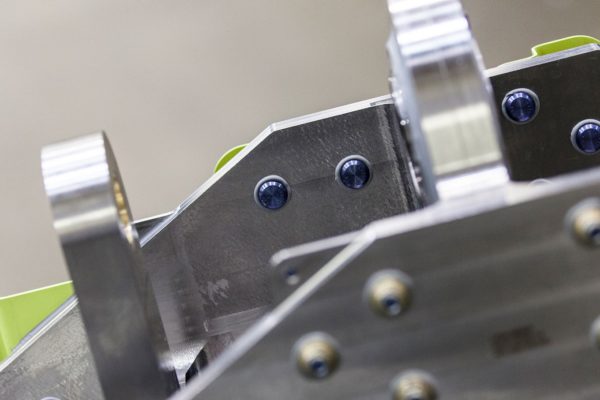

Sheet metal wheeling

Products produced by the wheeling process have several key advantages over other methods of manufacture including flexibility, less tooling requirements and suitability for prototype parts and aircraft skin panels.

Tube & pipe forming

Capabilities include forming 3/16” (5.0mm) to 3.0” (75mm) diameter pipes in aluminium and stainless steels to a min 1D bend radius.